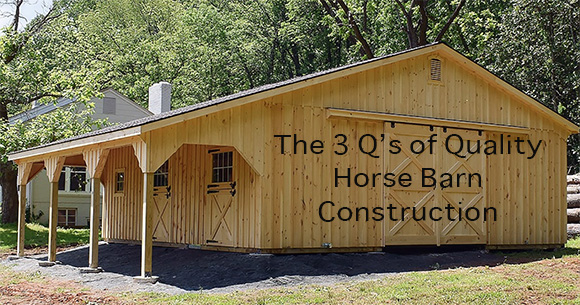

The 3 Q’s of Quality Horse Barn Construction

by Nikki Alvin-Smith

There are three simple rules to follow when you are on the hunt for a new horse housing and as quality of the barn build is often high on the list of concerns for horse owners, these are the top three questions you should address in your search.

Q1: Design

If you’ve ever had to manoeuvre a 17hh horse through a 36 inch wide stall door, or cringe nervously as you watch your horse rearing in his stall wanting his grain or turnout when he is boxed in a stable with a low wooden door and no grill, then you’ll appreciate that design plays an important part in horse barn safety and functionality.

New horse owners in particular are not necessarily savvy to the perils that can lie in a poorly designed horse barn. If you don’t want your new horse barn to be a hazard it’s wise to plan ahead and choosing a company that is staffed by horse people that can specifically address a horse’s needs and equine owner’s wants can save much heartache. There are lot of factors that affect the satisfaction and safety of daily use. As everyone is aware horses can be unpredictable and space that is properly constructed and finished is paramount to the success of its use and daily abuse horses can and will dish out.

Gone are the days of the straight stalls for horses. Economic perhaps and today still used for cows in stanchions, even the renowned Lippizzans of the Spanish Riding Schoolno longer reside at the palace in their stonewalled straight stalls that offer no mobility for the horse or opportunity it to lay down. Today’s design options come in low maintenance modern materials for siding and roofing, improved longevity in paint and sealants and offer every sort of style from traditional budget friendly shedrows and L-shapes to traditional monitors to classic “American” center aisles.

Horses don’t come in one shape and size, so why should horse barns? Think outside the box and ask lots of questions to garner design ideas. All designs should be approved by an engineer for safety and accurately executed plans are a must. Websites provide a great resource and a lot of footwork can be saved by diligent research from your armchair.

Q2: Materials

A barn is a big structure and many components go into the build. All of those components are not visible once the project is complete. It is important that the structure is sound and has the proper integrity to withstand snowloads, hurricanes or other factors that are  required by the region in which the barn will be sited.

required by the region in which the barn will be sited.

Materials used obviously affect the quality of that structure. Think of the difference in materials used as you would for those in your home. For example, when building a house interior walls will most likely be covered with ½ inch standard sheetrock where seams are easily taped before painting. The sheetrock will be designed to be cost effective in large sheets, that have to serve as walls so have to have rigidity. However standard sheetrock actually has little other benefit as it is not considered structural in terms of adding strength or integrity to the building. On the other hand, firerock is a type of sheetrock that is not just better designed to hold back flames and fire, but also is completely differently constructed from its counterpart. It is heavier, and provides better sound insulation and adds strength to the structure. It is also much harder to tape seamlessly and more expensive, but its use will give the building a more grounded and solid feel and that is actually truly more structurally sound. In modern building, the code requires firerock usually between an attached garage and the house but nowhere else. The choice of material is up to the builder.

In comparison if you build a horse stall with oak or cypress partitions, made of large lumber correctly attached to solid corner posts versus the kickboards will add strength to the building. If instead you opted for a thinner option of board such as standard grade 2 (with lots of knots), ½’’ inch tongue and groove pine, the resulting wall would offer far less strength and could even pose a danger if it was cracked or punctured by an errant horse’s kick. The application of heavy duty tongue and groove Southern pine over thick dimensional lumber can add extra protection as kickboards.

The use of modern day components such as vinyl or cementboard siding can save much labor down the road with repainting and resealing, but choice of which manufacturer and type of product can be a minefield of decisions. Warranties are extremely important and the latest product is not always the best as it is unproven. You certainly don’t want your horse barn built with a local construction company’s leftovers.

From top to bottom and in-between, in the doors, windows, grills and hardware, the horse barn construction is best completed by the most competent experienced company you can find that truly knows all the available materials and which ones work and which ones don’t. A company that is well-versed and very experienced working across all the material platforms will have tried and tested thousands of products over the years.

Q3: Craftsmanship

It may seem that a barn is just “grab a hammer and nails and put it together” kind of deal. It could be, and let’s face it in the past it has been. Farmers are a thrifty lot and not all farmers back in the day had any option but to pull some logs out of their woodlot with trustworthy “ Belgian Bessie,” mill them and bang them together off wobbly homemade wooden ladders.

If you are not too worried about what size nails are used for what purpose and whether they are correctly placed and are of the right strength to do the job or where a bolt should be used rather than a nail? Or whether you can use screws? Or if the roof may collapse or has been properly supported and constructed etc. then go right ahead and have a barn building party with a few mates. The late Patrick Swayze, actor and dancer, did just that when constructing his first horse farm.

That could be a bit of a ‘hit and miss’ option. Literally and figuratively. Friends may show up once or twice to help but staying power is probably limited to how hot the weather, how high the ladder is and when the beers and barbeque is scheduled. I once witnessed a roofing firm installing the underlay sheathing layer of a large house, and the crew had been hastily thrown together at the last minute. As I watched from below nearly ever nail from their nail guns entirely missed the rafters, rendering the sheathing useless with almost no attachment. Experience does count!

A company that provides an all year round working environment within a factory, can assemble a modular barn with proper quality control over all facets of the build including having all the necessary materials on hand and ready to go, with a crew that knows how to correctly apply said products to avoid breaking the manufacturers warranty.

The well-known hard-working Amish with their top quality craftsmanship and pride in a job well done are popular among the horse community as construction agricultural buildings specialists, (and indeed many other types too including log homes and houses), for good reason. Good carpenters offer a smarter choice than selecting a construction crew from a local builder that may be the crew boss’s son that seeks summer employment on college break or employs whoever they can find waiting for work on the street.

How Can You Address The 3 Q’s of Quality?

How are you best able to ascertain the answers to these important questions? There’s nothing better than kicking the tires when shopping for a car and nothing better than kicking the kickboards when selecting a partner to build your horse barn.

Transparency equals trust and you do need to trust your capital investment in a new structure to a company worthy of your confidence in both their product delivery and purchase process. Always ask lots of questions and DO go and look at buildings nearby that they have already built and talk directly with the folks that have made the acquisition. Horse people love to help other horse people out, and banking on that camaraderie is a smart step toward making your best barn selection. Look for an experienced producer of horse barns that provides a designated team member for your project. This will save a lot of back and forth and mitigate any likelihood of miscommunication.

We spoke with Chief Marketing Officer Jill Siragusa, a seasoned executive at a leading modular horse barn company, Horizon Structures L.L.C.. to find out how they address the transparency issue:

“It has long been our belief here at Horizon Structures, that integrity is everything in business. Our ethic is to do a better than good job, to always be there for our customers through every step of their barn purchase and we stand behind our products with firm warranties. As far as transparency we developed a handy ‘BarnFinder’ map that details the many variety of barn styles and sizes we have constructed across the country. We invite prospective clients to contact these barn owners directly, to visit and check out the structures both for ideas and for that opportunity to “kick the kickboards.”

Additionally Horizon Structures attends events to exhibit their modular and prefab buildings and is headed out to The Equine Affaire, Springfield, MA this November.

“ We go to Equine Affaire every year and our team member Brad Zeigler is a regular fixture at the event. People love to walk through the center aisle of our barns and chat with us about the many options we have available, and the structures we take to the event we sell either before or during the ‘affaire’ at a discount price to folks within a 300-mile delivery base of the show with no delivery charges. Of course you can find us at other events too. It is very important to give horse owners the opportunity to see our Amish quality craftsmanship first hand. As you can imagine there are many building companies out there to choose from, and not all are delivering on quality the way we take pride in doing. If you are headed to the show stop in and say Hi to Brad. He’ll brighten your day!” said Siragusa.

So don’t forget to tick off the important three Q’s in quality horse barn construction. It’s the best way to ensure longevity and happiness with your horse structure for years to come.